Invoice disputes are a common but costly reality of doing business. They can stem from minor issues like missing purchase order numbers or escalate into complex disagreements over pricing, delivery terms, or quantities

Purchasing v Procurement

What is Procurement and How is it Different to Purchasing?

Most of us know what purchasing entails – both as individuals and in the business world. Procurement, on the other hand, is a different story.

‘Procurement’ is often seen as an unnecessarily complex way of saying ‘purchasing’. A better understanding of what procurement is, and what it does, will make it clear these terms are not interchangeable.

There are some significant differences between the two – differences any organization operating in today’s business climate needs to know. Why? Because procurement is becoming increasingly important to sustainability and business resilience. Supply chains are more complex and unreliable, as companies face challenges in sourcing stock on time and in full. This can seriously impact their bottom line and force them to re-evaluate their inventory management processes.

Those that have already acknowledged the long-term nature of these challenges and opted to move towards a ‘procurement thinking’ approach have managed to stay ahead of the curve. Now, it’s your turn to make procurement a competitive advantage.

Let’s start with the fundamental differences between purchasing and procurement.

Purchasing v Procurement

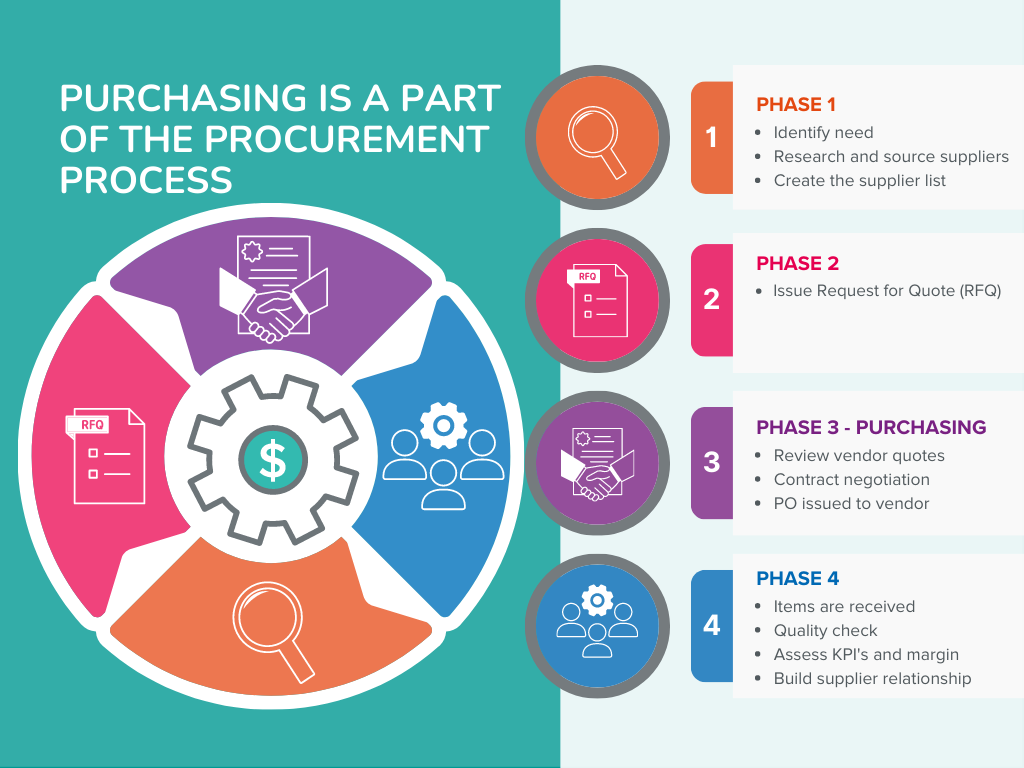

Purchasing and procurement may seem similar at first glance, but they actually refer to different stages of the acquisition process. Purchasing is the final step in procurement, where a purchase order is sent to a supplier and the supplier sends back an invoice to be paid. Procurement is the entire process of acquiring goods or services, including identifying needs finding and evaluating potential suppliers, negotiating contracts, working through multi-level approvals, managing requisitions, checking budgets, building relationships with chosen suppliers, and managing the RFQ process if required.

One key difference between purchasing and procurement is the level of involvement and decision-making. Purchasing is generally a transactional process focused on getting the best price for a specific product or service. Procurement involves a more strategic approach to acquiring goods and services, taking into account the long-term needs and goals of the organization.

Think of procurement as ‘next level’ purchasing. It not only involves the final step of buying a product or service but also harnesses the purchasing power of a business by organizing the entire acquisition process and optimizing it for efficiency and cost-effectiveness. Procurement also plays a crucial role in supply chain management and can involve implementing processes and systems, such as inventory management software, to streamline the process.

Here’s a table summarizing the key differences between purchasing and procurement:

Procurement v Procure-to-Pay

Another crucial distinction is the difference between procurement and procure-to-pay (P2P).

While procurement is the entire process of acquiring goods or services, P2P is a subdivision of that process. It refers to:

- The integration of purchasing and accounts payable systems

- Creating greater efficiency and transparency in the procurement process

- Automating and streamlining the process of acquiring goods and services, from the initial request to the final payment

P2P focuses specifically on integrating and automating the purchasing and accounts payable systems and has a much smaller scope than procurement. While procurement involves managing the complete lifecycle of a product or service, P2P incorporates the process of acquiring goods and services, from the initial request to the final payment. Both are important in ensuring an effective, efficient, and resilient procurement process for an organization.

The Evolution of Procurement

The practice of procurement has a long and storied history, with the oldest known form dating back to ancient civilizations. The term ‘procurement’, is derived from the Latin ‘procurare’, meaning ‘to take care of.’ In its earliest iterations, procurement involved the acquisition of goods and services for personal use or a community benefit.

As time passed, procurement evolved into a crucial aspect of modern business operations. Today, it can significantly impact a company’s profitability, with estimates suggesting that procurement can account for up to 70 per cent of an organization’s revenue. In a world with increasingly complex global supply chains and the proliferation of digital technologies, procurement has become a strategic function that encompasses a product’s or service’s entire lifecycle.

Why is Procurement so Important?

Procurement is crucial for any organization, and failing to embrace a procurement mindset can have a major impact on a business’s bottom line.

One of the key benefits of procurement thinking is cost savings. By taking a strategic approach to acquiring goods and services, procurement can help organizations negotiate better prices with suppliers and identify opportunities to cut expenses or increase value.

Procurement also enables greater control over purchasing processes. By centralizing and standardizing the procurement process, companies can reduce the risk of ‘maverick’ purchasing, where individuals or departments make purchases outside the approved procurement process. This can help businesses avoid overpaying for goods and services and ensure they receive the best value for money.

In addition to cost savings and greater control over purchasing processes, procurement also involves big-picture thinking. By looking at the organization’s overall needs and strategic objectives and how the acquisition of goods and services can support those goals, procurement can help teams make informed decisions that drive business success.

Finally, procurement can help businesses unlock their purchasing power and negotiate better prices with suppliers. Organizations can leverage their combined purchasing power to secure better deals and more favorable terms with suppliers, resulting in further cost savings and more reliable and consistent supply chains.

What’s Next?

In our next article, we will delve into the priorities and challenges currently facing procurement professionals, as well as what the future holds for the procurement function. Stay tuned as we explore the process of transitioning from a purchasing mindset to a procurement mindset and discover the many benefits you can gain from this shift.

Inspired to Act?

Book a Discovery Call with one of our product specialists to learn more about how procurement technologies can transform your business.

Subscribe to our LinkedIn Newsletter and get alerts when we post about topics that matter to you.

Related Articles

Transforming Expertise into Assets: The Next Frontier for Manufacturers

Many manufacturers reach a point where growth outpaces their systems. Success relies not just on people, but on turning expertise into scalable assets. The next frontier is building resilient businesses where knowledge lives in systems, not just in minds.

Balancing Standard Functionality and Customisation in ERP Solutions

ERP solutions streamline manufacturing operations, balancing standard functionality with essential customisation. While out-of-the-box features enable faster deployment and cost savings, customisation supports unique workflows and business growth. However, excessive modifications can increase costs and maintenance challenges. The key is partnering with ERP experts to optimise functionality without unnecessary complexity.

Epicor ARM 2024.2.2 Released

Unlock smarter procurement with Epicor ARM 2024.2.2! From flexible approval workflows to seamless invoice matching, this release is packed with customer-focused improvements to boost efficiency and control. Discover how the latest Epicor ARM enhancements can streamline your procurement and AP management, making it smarter, faster, and more efficient!

Unlock Seamless UI Testing with Kinetic’s Test ReCoder Tool

Kinetic customers can now harness the power of the Test ReCoder UI Test Tool to set their QA processes on a smarter, faster track! This core enhancement in the latest Kinetic release (2024.2) is loaded with benefits including reduced test execution time, lower error rates, and enhanced productivity.

Epicor Kinetic’s Answer to SQL Bottlenecks

Epicor Kinetic’s SQL to BAQ Generator simplifies data analytics and streamlines workflows by converting SQL queries into intuitive, easy-to-use BAQs.