Invoice disputes are a common but costly reality of doing business. They can stem from minor issues like missing purchase order numbers or escalate into complex disagreements over pricing, delivery terms, or quantities

Elevate ETO Operations with ERP

Unlocking the Full Potential of Custom Manufacturing with Advanced ERP Systems

Manufacturing businesses are continuously seeking ways to enhance their operational efficiency. For those engaged in Engineer-to-Order (ETO) manufacturing, the complexity and customisation required in every project present unique challenges. Implementing an Engineer-to-Order ERP solution can significantly transform operations, providing enhanced visibility and control over every aspect of manufacturing.

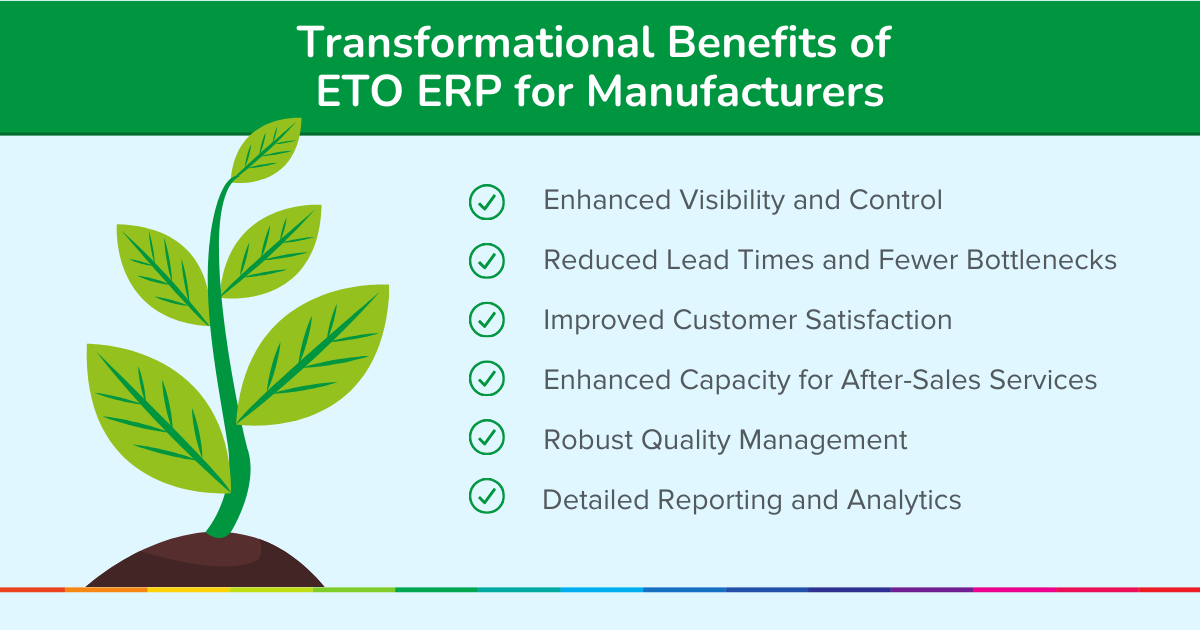

This transformation yields numerous benefits, including reduced lead times, fewer production bottlenecks, improved customer satisfaction, and an increased capacity for after-sales services. Additionally, these systems offer robust tools for quality management and detailed reporting, ensuring that high standards are consistently met.

In this article we delve into the key benefits ETO manufacturers can expect from implementing Engineer-to-Order ERP solutions.

Transformational Benefits of ETO ERP for Manufacturers

Enhanced Visibility and Control

One of the most critical advantages of an ETO ERP solution is the improved visibility and control it offers over the manufacturing process. By integrating all facets of production—from initial design and engineering through to final delivery—an ETO ERP system provides a centralised platform where manufacturers can monitor and manage every detail. This holistic view allows for better planning and coordination, ensuring that each project progresses smoothly and efficiently.

Reduced Lead Times and Fewer Bottlenecks

Reducing lead times is crucial in ETO manufacturing, where each product is tailored to specific customer requirements. An ETO ERP solution streamlines the workflow by automating various processes, from order entry to production scheduling. This automation eliminates redundant tasks and minimises delays, leading to significantly reduced lead times.

Moreover, the system’s ability to provide real-time updates and insights helps identify and address potential bottlenecks before they escalate. By proactively managing these issues, manufacturers can maintain a steady production flow, ensuring projects are completed on time.

Improved Customer Satisfaction

Faster delivery times are a direct result of reduced lead times and efficient production processes, and they play a crucial role in enhancing customer satisfaction. Customers today expect quick turnaround times and timely delivery of high-quality products. An ETO ERP system enables manufacturers to meet these expectations by optimising every step of the production process.

Additionally, better communication and transparency with customers are facilitated through the ERP system’s customer portals, where clients can track the progress of their orders and stay informed about any updates or changes. This level of engagement fosters trust and strengthens customer relationships.

Enhanced Capacity for After-Sales Services

After-sales services are a vital component of customer satisfaction and long-term loyalty. An ETO ERP solution enhances the capacity for after-sales support by providing tools for managing maintenance schedules, service requests, and repairs. The system keeps detailed records of each product’s history, enabling quick and efficient service responses.

By ensuring that after-sales services are prompt and effective, manufacturers can address any issues that arise post-delivery, further cementing customer loyalty and satisfaction.

Robust Quality Management

Maintaining high standards in ETO manufacturing is non-negotiable, and quality management tools within an ETO ERP system are crucial for this purpose. These tools enable rigorous quality control at every stage of the manufacturing process, from initial design to final inspection.

The ERP system can automate quality checks and maintain comprehensive records, ensuring that each product meets the specified standards. By embedding quality management into the production process, manufacturers can reduce defects, minimise rework, and ensure that customers receive products of the highest quality.

Detailed Reporting and Analytics

Detailed reporting and analytics are essential for continuous improvement and strategic decision-making. An ETO ERP solution provides powerful reporting tools that offer insights into every aspect of the manufacturing process.

These reports can cover a wide range of metrics, including production efficiency, cost analysis, lead times, and quality control. By analysing this data, manufacturers can identify trends, uncover inefficiencies, and make informed decisions to enhance overall operational performance.

Selecting Engineer to Order ERP Software

Epicor is renowned for its flexibility and industry-specific ERP features designed to address the complex requirements of ETO companies. Epicor’s ETO ERP software is considered one of the top products on the market to manage the unique project management, engineering design, and production planning challenges of ETO manufacturing.

The Wrap

Implementing an Engineer-to-Order ERP solution is a strategic move that can significantly elevate operational efficiency in ETO manufacturing. By providing better visibility and control, reducing lead times and production bottlenecks, and improving customer satisfaction through faster delivery times, these systems transform the manufacturing process. Additionally, the enhanced capacity for after-sales services, coupled with robust quality management tools and detailed reporting, ensures that manufacturers can maintain high standards and continuously improve their operations.

In an industry where customisation and precision are paramount, an ETO ERP solution is an indispensable tool for achieving excellence and staying competitive.

Ready to Elevate Operational Efficiency in Your Manufacturing Business?

Precise Business Solutions has worked with many Engineer-to-Order (ETO) manufacturers over the years to implement purpose-built Epicor ERP manufacturing solutions that meet the challenges of rapid continuous change, increased competition and high customer expectations.

And if you have a bottleneck in your manufacturing systems or processes that you can’t put your finger on, we can help you identify bottleneck root causes and what this is costing your business.

Connect with us today to see how Epicor’s ETO ERP software can unlock the full potential of your manufacturing business.

Inspired to Act?

Book a Discovery Call with one of our product specialists to learn more about how an experienced ERP implementation partner can support a smooth ERP migration.

Subscribe to our LinkedIn Newsletter and get alerts when we post about topics that matter to you.

Related Articles

Transforming Expertise into Assets: The Next Frontier for Manufacturers

Many manufacturers reach a point where growth outpaces their systems. Success relies not just on people, but on turning expertise into scalable assets. The next frontier is building resilient businesses where knowledge lives in systems, not just in minds.

Balancing Standard Functionality and Customisation in ERP Solutions

ERP solutions streamline manufacturing operations, balancing standard functionality with essential customisation. While out-of-the-box features enable faster deployment and cost savings, customisation supports unique workflows and business growth. However, excessive modifications can increase costs and maintenance challenges. The key is partnering with ERP experts to optimise functionality without unnecessary complexity.

Epicor ARM 2024.2.2 Released

Unlock smarter procurement with Epicor ARM 2024.2.2! From flexible approval workflows to seamless invoice matching, this release is packed with customer-focused improvements to boost efficiency and control. Discover how the latest Epicor ARM enhancements can streamline your procurement and AP management, making it smarter, faster, and more efficient!

The Hidden Risks of Managing Business Processes with Spreadsheets

Spreadsheets have long been a go-to tool for managing business processes, but as companies grow, they often expose hidden risks. While spreadsheets might work for small-scale tasks, relying on them for critical business operations can lead to inefficiencies, errors, and data security issues. To stay competitive and efficient, businesses must explore more robust solutions like ERP software. In this blog, we’ll look at the most common problems with spreadsheets and how enterprise resource planning solutions offer a better way to manage business processes.

Most Common Problems With Inconsistent Business Processes & How To Fix Them

Inconsistent business processes can slow down operations, increase costs, and lead to inefficiencies. Identifying and fixing these issues is essential for smoother operations. Here are the most common problems with inconsistent processes and how ERP software solutions can help address them.