ERP solutions streamline manufacturing operations, balancing standard functionality with essential customisation. While out-of-the-box features enable faster deployment and cost savings, customisation supports unique workflows and business growth. However, excessive modifications can increase costs and maintenance challenges. The key is partnering with ERP experts to optimise functionality without unnecessary complexity.

Software to Optimise Manufacturing

Unleash the Power of Manufacturing Software for Sustainable Growth

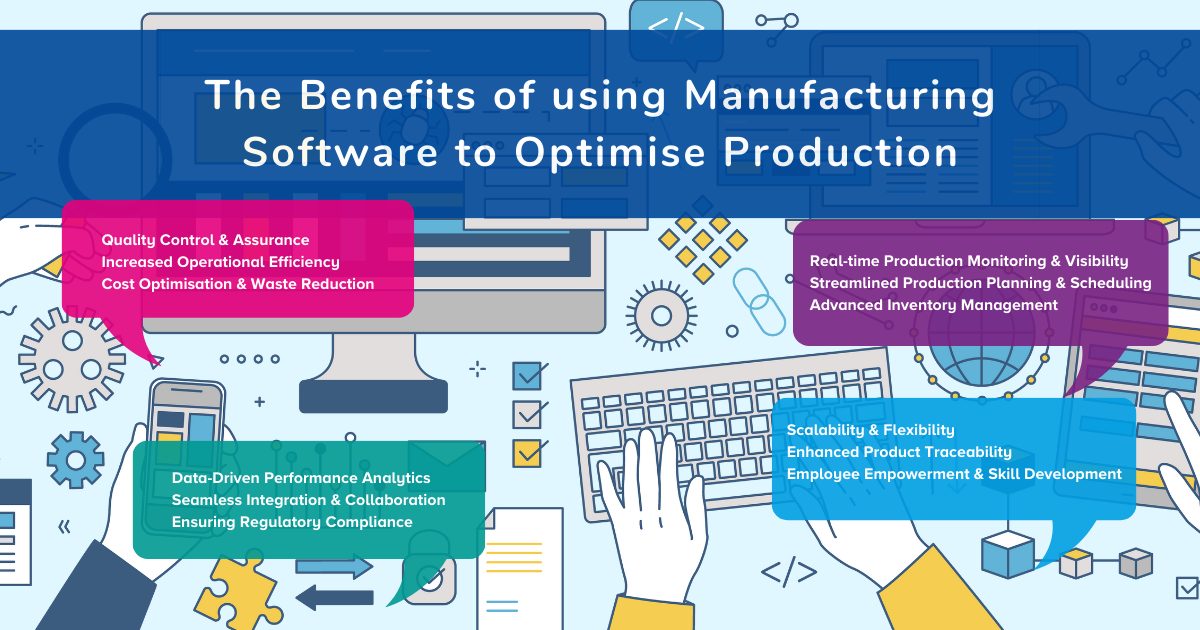

Ready to take your manufacturing business to new heights? Enter manufacturing software—a game-changer that optimises production and processes.

Discover manufacturing software benefits and how it boosts efficiency, cuts costs, and enhances product quality.

Let’s embrace the future of manufacturing and revolutionise your business together.

The Modern Challenges of Manufacturing

Are you a part of the manufacturing industry, striving to stay ahead in today’s fast-paced world?

Manufacturing has come a long way, embracing technological advancements and innovative practices. However, with progress comes unique challenges that demand agile solutions.

With competition intensifying and customer expectations on the rise, today’s manufacturers face several critical challenges:

- Global Competition: The global market has opened up, exposing manufacturers to increased competition from all corners of the world. Staying competitive means streamlining operations and maximising efficiency.

- Complex Supply Chains: Supply chains have become more intricate, making it essential to manage logistics, inventory, and production processes with precision.

- Quality, Compliance, and Traceability: Meeting stringent quality standards, financial requirements, and industry regulations is crucial to maintain credibility and customer trust.

- Rising Customer Demands: Customers expect faster turnaround times, customised products, and real-time updates on their orders.

- Cost Pressures: Managing production costs while maintaining quality and efficiency is a constant challenge.

- Operational Visibility: Real-time visibility into production processes and key performance indicators is essential for informed decision-making.

Optimising Production v Optimising Production Processes

To understand the benefits of using manufacturing technology to support optimising production and production processes, let’s first define the differences between these two terms.

“Manufacturing software to optimise production” focuses on enhancing overall production efficiency and output in manufacturing operations. It encompasses various software tools and systems designed to improve the entire production process, from raw materials to the final product.

On the other hand, “manufacturing software to optimise production processes” narrows its focus to specific processes within manufacturing.

Production process optimisation tools target individual production stages or areas that require optimisation, identifying and improving bottlenecks, inefficiencies, and quality issues within each process.

Role of Manufacturing Software in Streamlining Operations and Optimising Production Processes

Let’s look at the ways manufacturing software streamlines operations and optimises production processes:

Optimised Production Scheduling

- Well-organised production plans can be created that consider essential factors like resource availability, lead times, and customer demands.

- Production processes align with market demand, minimising downtime and maximising output.

Real-Time Visibility and Insights

- Live data visibility into business performance and inventory provides insights into the current state of production.

- Real-time production monitoring enables the proactive resolution of issues like bottlenecks, streamlined processes, and improved operational efficiency.

Enhanced Efficiency and Productivity

- Automated and streamlined workflows along with standardised processes reduce manual interventions and supports eliminating bottlenecks leading to faster production cycles and reduced errors.

- Increased efficiency translates to cost savings, reduced downtime, minimised material waste, shorter lead times, and improved competitiveness in the market.

Quality Control and Compliance

- Manufacturing software that includes modules for quality control will ensure products consistently meet stringent quality standards and regulatory requirements.

- Real-time monitoring and data-driven analysis help identify and rectify quality issues, improving product quality and customer satisfaction.

Resource Optimisation

- Insights into resource utilisation enables better management of materials, human resources, and machinery.

- Optimal resource allocation reduces wastage and ensures resources are utilised to their fullest potential, contributing to cost savings.

Continuous Improvement Initiatives

- Data-driven analysis allows you to monitor the impact of improvement efforts and refine processes for ongoing optimisation.

- Streamlined production processes enhance your ability to adapt quickly to changing market demands and customer requirements.

Streamlined Supply Chain Management

- Integrating manufacturing software with supply chain management simplifies the flow of materials and information across the supply chain.

- Improved coordination with suppliers and customers facilitates better demand forecasting and inventory management and accelerated time-to-market of products.

Importance of Optimising Production Processes

Optimising production processes with manufacturing software yields a multitude of benefits that can significantly impact your manufacturing business:

- Enhanced Efficiency: By streamlining workflows and eliminating bottlenecks, you can achieve higher levels of operational efficiency.

- Improved Product Quality: Manufacturing software enables better quality control, ensuring products consistently achieve quality standards.

- Faster Time-to-Market: Optimised production processes can accelerate the time-to-market for your products, gaining a competitive edge in the fast-paced manufacturing industry.

- Manufacturing software for cost reduction: Efficient production processes lead to cost savings by minimising material waste, reducing downtime, and optimising resource allocation. This helps lift your manufacturing software ROI.

- Agility, Scalability, and Flexibility: Streamlined production processes enhance your ability to adapt quickly to changing market demands and customer requirements.

How an ERP Supports Optimising Production and Production Processes

ERP’s Role in Optimising Production

An ERP system is crucial in optimising production at a broader level, focusing on factors that influence the entire production operation. Here’s how ERP software improves production:

- Demand Planning: ERP systems include demand forecasting modules that analyse historical data and customer orders. By accurately predicting demand, you can optimise production schedules, minimise excess inventory, and ensure products are available when needed.

- Resource Planning: ERP systems provide insights into resource availability. You can optimise resource allocation to meet production demands and avoid underutilisation or overutilisation.

- Production Scheduling: ERP systems help create and manage production schedules, considering various constraints like resource availability, lead times, and delivery deadlines. Optimising production scheduling with software cuts downtime and improves throughput.

- Real-time Visibility: With real-time data, an ERP system allows production managers to monitor the progress of production in real time. This visibility helps identify any deviations from the plan and enables quick decision-making to keep production on track.

ERP’s Role in Optimising Production Processes

An ERP system also optimises individual production processes within the larger production context. Here are some production process optimisation advantages with an ERP:

- Data-driven Analysis: ERP systems collect and store granular data about various production processes. Manufacturing analytics software benefits manufacturers by allowing them to identify bottlenecks, inefficiencies, and areas for improvement within each individual process.

- Quality Control: By tracking and analysing quality data, you can identify trends and patterns related to defects and take corrective actions to optimise the production process.

- Streamlining Production Processes: ERP systems allow you to define standardised workflows and automate repetitive tasks, reducing manual intervention.

- Process Standardisation: ERP systems promote process standardisation across different production units or locations, ensuring consistent and optimised practices throughout the organisation.

An ERP system’s integration of data and functionalities empowers organisations to optimise both production and production processes. This leads to higher levels of efficiency, reduced costs, improved product quality, and enhanced customer satisfaction.

Start enhancing operational efficiency with software today. Embrace the power of an ERP system and witness transformative results in your manufacturing operations.

Inspired to Act?

Book a Discovery Call with one of our product specialists to learn more about how an ERP system can transform your business.

Subscribe to our LinkedIn Newsletter and get alerts when we post about topics that matter to you.

Related Articles

Epicor ARM 2024.2.2 Released

Unlock smarter procurement with Epicor ARM 2024.2.2! From flexible approval workflows to seamless invoice matching, this release is packed with customer-focused improvements to boost efficiency and control. Discover how the latest Epicor ARM enhancements can streamline your procurement and AP management, making it smarter, faster, and more efficient!

The Hidden Risks of Managing Business Processes with Spreadsheets

Spreadsheets have long been a go-to tool for managing business processes, but as companies grow, they often expose hidden risks. While spreadsheets might work for small-scale tasks, relying on them for critical business operations can lead to inefficiencies, errors, and data security issues. To stay competitive and efficient, businesses must explore more robust solutions like ERP software. In this blog, we’ll look at the most common problems with spreadsheets and how enterprise resource planning solutions offer a better way to manage business processes.

Most Common Problems With Inconsistent Business Processes & How To Fix Them

Inconsistent business processes can slow down operations, increase costs, and lead to inefficiencies. Identifying and fixing these issues is essential for smoother operations. Here are the most common problems with inconsistent processes and how ERP software solutions can help address them.

Unlock Seamless UI Testing with Kinetic’s Test ReCoder Tool

Kinetic customers can now harness the power of the Test ReCoder UI Test Tool to set their QA processes on a smarter, faster track! This core enhancement in the latest Kinetic release (2024.2) is loaded with benefits including reduced test execution time, lower error rates, and enhanced productivity.

Enhancing Process Efficiency: Proven Strategies, Essential Tools, and Best Practices

Efficient processes drive business success, enabling companies to streamline operations, cut costs, and improve productivity. To achieve process efficiency, businesses need a combination of the right strategies, tools, and practices. In this guide, we will explore how ERP software solutions with industry-specific tools can enhance your operational efficiency.