ERP solutions streamline manufacturing operations, balancing standard functionality with essential customisation. While out-of-the-box features enable faster deployment and cost savings, customisation supports unique workflows and business growth. However, excessive modifications can increase costs and maintenance challenges. The key is partnering with ERP experts to optimise functionality without unnecessary complexity.

ERP and Workforce Productivity

Optimising Workforce Efficiency: The Role of ERP Systems

More than one in four businesses have current job vacancies, and 36% believe skills shortages will limit future growth.

The manufacturing industry is feeling the heat of these challenges. Many major manufacturing bottlenecks—from manual errors and disjointed communication to poor resource allocation—can be tied back to workforce constraints.

There is, however, a solution, one that doesn’t depend on manual labour. Maximising manufacturing efficiency with enterprise resource planning (ERP) systems enables organisations to adapt, automate, and thrive.

Why is Addressing Workforce Constraints Important?

Workforce constraints can quickly become your operation’s most detrimental bottlenecks. Let’s explore why tackling these issues head-on leads to a smoother, more efficient, and more profitable manufacturing process.

Maximising manufacturing efficiency

A well-oiled machine requires more than high-quality materials and state-of-the-art technology. It demands a skilled, well-distributed team.

Why? Because the strength and efficiency of your workforce directly influence your operation’s productivity. When you’re facing a shortage of skilled labour or your resources aren’t allocated effectively, your production lines suffer.

This slows the manufacturing process and drives up the cost of each unit produced. Identifying and addressing these workforce constraints ensures your operations can run at full throttle.

This is where proactive workforce planning strategies with ERP come into play. These enable a streamlined allocation of resources so that every part of your manufacturing process is optimised for peak performance.

Meeting customer demand

Speed and reliability are paramount, and the ability to meet customer demand fast is non-negotiable. Workforce bottlenecks can delay order fulfilment, extend lead times, and ultimately diminish customer satisfaction.

Reducing costs

Workforce constraints don’t just slow down production. They’re also a quick route to increased operational costs.

Think about it: overtime pay, the expense of hiring temporary workers, and the costs associated with training new staff to close skill gaps all add up. Not to mention the inefficiencies stemming from these bottlenecks, which can lead to wasted materials, underused equipment, and soaring operational expenses.

Improving quality and consistency

When your team is stretched thin and lacking necessary skills or resources are scarce, the risk of errors, defects, and inconsistencies skyrockets. Yes, there’s an immediate fallout in product quality. But perhaps more concerning is the long-term impact on your brand’s reputation and market position.

ERP workforce management ensures that your team is well-equipped, well-trained, and ready to maintain the high standards your customers expect.

Enhancing employee morale and retention

Consider the human side of workforce constraints. Overworked employees, skill gaps, and the lack of proper tools lead to operational inefficiencies. They also affect morale and job satisfaction, which can escalate into higher turnover rates and make it challenging to attract new talent. This cycle can destabilise the very foundation of your manufacturing operations.

When you commit to optimising workforce scheduling with ERP systems, you signal to your employees that they are valued and supported.

How ERP Systems Can Effectively Address Workforce Constraints

The strategic use of ERP systems can help you overcome workforce management challenges and constraints. Here’s how.

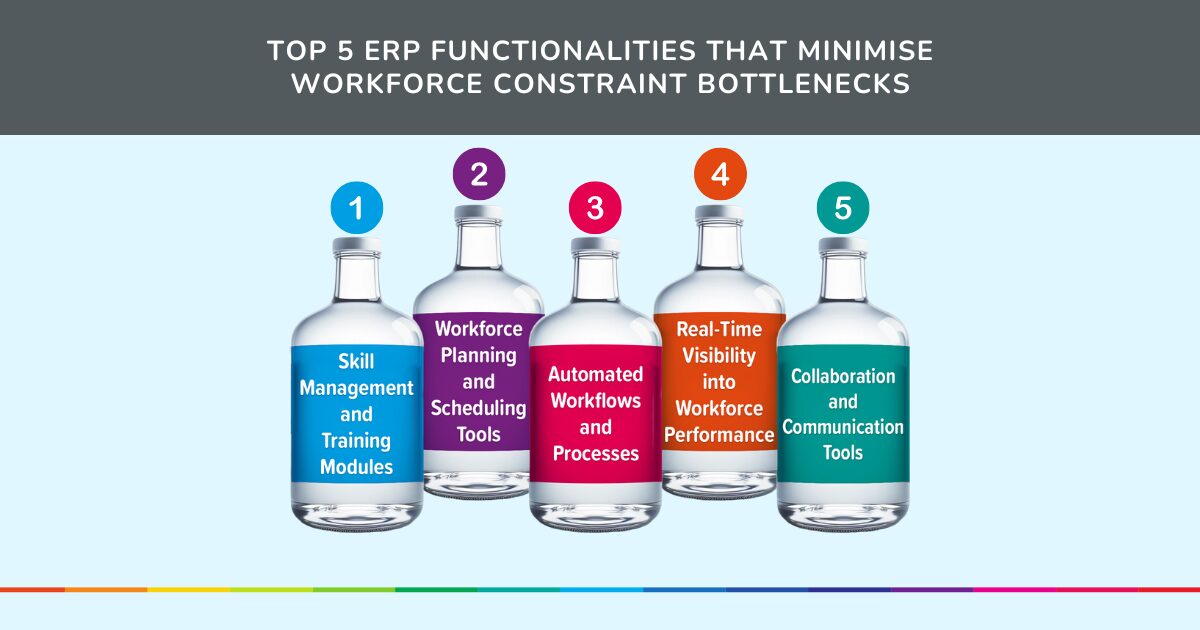

Skill management and training modules

Industry-ready ERP systems feature skill management and training modules. These offer a comprehensive, 360-degree overview of your workforce’s capabilities and development needs.

With workforce planning capabilities as a core ERP feature, you can identify existing skill gaps within your team. What does this mean for your operations? You can pinpoint exactly where your team’s strengths lie, where improvement is needed, and implement targeted training programs to meet current and future skills gaps.

This insight is invaluable in today’s fast-paced, tech-driven market, where agility and adaptability are key to staying competitive.

By mitigating workforce constraints through an ERP’s skill management module, you invest in continuous improvement and professional development.

This approach enhances your team’s capability and contributes to higher employee satisfaction and retention. Workers who feel supported are more likely to be engaged, motivated, and committed to your company’s success. Organisations that lead the way in employee engagement and experience achieve double the customer satisfaction and twice the innovation. This results in 25% greater profitability than their competitors.

Workforce planning and scheduling tools

ERP-powered workforce planning and scheduling tools foster a more dynamic and responsive manufacturing environment.

With ERP’s real-time visibility into workforce availability, skill sets, and capacity, you can precisely align labour with production schedules, anticipated demand, and resource availability. The result? A perfectly balanced equation where your workforce is optimally allocated, skill shortages are effectively mitigated, and resources are utilised to their fullest potential.

This approach almost entirely eliminates the guesswork from workforce planning. That’s the power of ERP systems—they provide a strategic framework that guarantees you have the right personnel, with the right skills, exactly where and when you need them.

Automated workflows and processes

ERP automation workforce solutions improve labour utilisation. They transform the way manufacturing operations are conducted, streamlining workflows and automating routine tasks to reduce manual errors and free up valuable time for growth-driving decision-making. This lessens your dependency on manual labour thereby minimising the impact of workforce shortages.

Consider the tasks that consume a significant portion of your team’s day—inventory management, production scheduling, and order processing. Automation unlocks a new level of ERP productivity optimisation. That way, you can maintain high consistency and quality standards by maximising workforce productivity with ERP solutions, even amid a skills shortage.

Real-time visibility into workforce performance

Real-time workforce performance tracking with ERP systems provides a holistic view of your workforce’s activities and efficiencies. With this level of insight, you can pivot quickly, address inefficiencies, and optimise operations on the fly.

Real-time visibility isn’t just about keeping tabs on your workforce. It’s about empowering decision-makers with the meaningful and actionable data needed to make informed choices. Whether reallocating resources to meet production goals or identifying training opportunities to enhance skills, an ERP system can boost workforce efficiency and enable a previously unattainable level of agility.

Collaboration and communication tools

The ability to collaborate and communicate can be the difference between success and stagnation. ERP collaboration tools can help break down barriers and foster an environment where ideas flow freely.

By enhancing collaboration in manufacturing using ERP tools, every team member—regardless of department or location—has access to the information they need when they need it. This seamless flow of data promotes a culture of teamwork, where collective efforts lead to innovative solutions and more efficient problem-solving.

The Wrap

If you need to boost workforce efficiency, ERP systems offer a comprehensive toolkit. They ensure every aspect of workforce management aligns with your company’s strategic goals. At the same time, they reduce your reliance on manual labour, removing bottlenecks and safeguarding productivity by mitigating workforce constraints.

Addressing skill shortages in manufacturing through ERP paves the way for innovation. It nurtures a culture of continuous improvement, setting the stage for success in the digital manufacturing landscape.

Is your business seeking a solution to maximise workforce productivity and efficiency? Talk to us today.

Inspired to Act?

Book a Discovery Call with one of our product specialists to learn more about how an ERP system can transform your business.

Subscribe to our LinkedIn Newsletter and get alerts when we post about topics that matter to you.

Related Articles

Epicor ARM 2024.2.2 Released

Unlock smarter procurement with Epicor ARM 2024.2.2! From flexible approval workflows to seamless invoice matching, this release is packed with customer-focused improvements to boost efficiency and control. Discover how the latest Epicor ARM enhancements can streamline your procurement and AP management, making it smarter, faster, and more efficient!

The Hidden Risks of Managing Business Processes with Spreadsheets

Spreadsheets have long been a go-to tool for managing business processes, but as companies grow, they often expose hidden risks. While spreadsheets might work for small-scale tasks, relying on them for critical business operations can lead to inefficiencies, errors, and data security issues. To stay competitive and efficient, businesses must explore more robust solutions like ERP software. In this blog, we’ll look at the most common problems with spreadsheets and how enterprise resource planning solutions offer a better way to manage business processes.

Most Common Problems With Inconsistent Business Processes & How To Fix Them

Inconsistent business processes can slow down operations, increase costs, and lead to inefficiencies. Identifying and fixing these issues is essential for smoother operations. Here are the most common problems with inconsistent processes and how ERP software solutions can help address them.

Unlock Seamless UI Testing with Kinetic’s Test ReCoder Tool

Kinetic customers can now harness the power of the Test ReCoder UI Test Tool to set their QA processes on a smarter, faster track! This core enhancement in the latest Kinetic release (2024.2) is loaded with benefits including reduced test execution time, lower error rates, and enhanced productivity.

Enhancing Process Efficiency: Proven Strategies, Essential Tools, and Best Practices

Efficient processes drive business success, enabling companies to streamline operations, cut costs, and improve productivity. To achieve process efficiency, businesses need a combination of the right strategies, tools, and practices. In this guide, we will explore how ERP software solutions with industry-specific tools can enhance your operational efficiency.